Flax

FLAX

Crop Profile

Get Involved!

Flax (Linum usitatissimum) is a flowering plant that is cultivated for both its seeds and fibers and, occasionally, cut flowers. It is one of the oldest cultivated plants and has been used by humans for thousands of years. Flax is primarily grown in cooler regions of the world, including Europe, North America, and Asia. France, Belgium and Netherlands lead the world in the cultivation of flax for fiber. In North America, flax is predominantly grown for seed with North and South Dakota and Saskatchewan as leading producers. The soil and climate throughout Wisconsin are well suited to grow flax for both seed and oil.

The flax plant has a slender stem that can reach a height of around three feet. The plant produces attractive blue flowers, blooming for a single day. Flax seeds are small and flat, and they are rich in nutrients, particularly omega-3 fatty acids, fiber, and lignans. The fibers from the stem of the flax plant are used to produce linen, a durable and breathable textile.

Flax fibers are found in a ring between the bark and the inner part of the stem, and they are obtained through a process called retting. After retting, the fibers are separated, dried, and spun into yarn or thread, which is then used to weave linen fabric. Flax fibers have been historically used in the manufacturing of paper and rope as well.

Today, long line wet spun flax yields highly desirable luxury textiles specified by high- end fashion and homegoods designers. This versatile fiber is useful in lightweight outdoor sportswear as well. In addition, lesser quality fibers, known as tow, can be used in the manufacture of geotextiles, in horticultural applications to reduce or eliminate weed growth and for flax fiber to replace fiberglass in plastic composites.

Flax is a valuable crop due to its versatility and offers a more sustainable alternative to fast fashion. It requires fewer pesticides and water compared to other crops used in textile production, such as cotton. Clothing made from synthetic fibers like polyester, nylon, and acrylic releases microfibers and nano-plastics into the environment, which last for hundreds of years in landfills and contribute to climate change by perpetuating our reliance on the fossil fuels used in textile production. As its botanical name declares, flax is the ‘most useful plant’; the entire plant can be used, making it a more environmentally friendly choice.

Flax seeds have various culinary uses and are commonly consumed for their nutritional benefits. They can be ground into flaxseed meal and added to smoothies, cereals, baked goods, or used as an egg substitute in vegan recipes. Flaxseed oil, derived from the seeds, has a very low smoke point of 225°F, so is not an ideal cooking oil, but is tasty and useful in salad dressings and sauces and as a nutritional supplement. The flax cake residue from pressing the seeds for oil is a highly nutritious animal feed supplement. The oil extracted from flax seeds is also used in the production of paints, varnishes, and linoleum.

For fiber flax to succeed as a diversified crop, we must simultaneously increase acres under cultivation, mechanized capacity to harvest and process the fiber, and the markets that the fiber will supply.

Perennial flax, Linum perenne, differs significantly from Linum usitatissimum, most notably in height. Perennial flax is grown mostly for seed and cut flowers. It may have some limited use for fiber. Further research and potential market development for secondary fiber use should be explored.

Production

Annual flax for fiber in Wisconsin thrives best when planted in early spring, as soon as the frost is out of the ground. The soil should be well drained with good seed bed preparation. Seeding rates and optimum stand densities for oilseed and fiber flax differ greatly. To maximize yield when growing for fiber, seeds are sown at a higher density, around 100 to 150 lb./acre. The optimum stand densities for fiber flax are 175 to 200 plants per square foot. Oilseed flax is planted at a rate of 30 to 40 lb. of seed per acre with an optimum stand density of about 30 plants per square foot. Seeds should be sown 0.75-1.5 inches deep and soil firmed to achieve good seed to soil contact.

Flax for fiber in Wisconsin typically does not require irrigation. Adequate moisture is essential during the early stages, but flax is relatively drought-tolerant during its later growth periods, making it a more climate resilient crop. Weed control, whether chemical or mechanical, is most important during the first few weeks after germination, until the plants are tall enough to outcompete the weeds. Planting flax in three to four year crop rotations with small grains helps control Fusarium rust and other fungal diseases.

Flax fiber plants are harvested before seed maturity, around 90-100 days after seeding. When the crop is harvested for seed, 90-120 days after seeding depending on the variety and conditions, the fiber is too coarse for fine long-line linen. Traditionally, flax plants were pulled from the ground by hand, shallow roots and all, which has the added benefit of leaving the field clear of residual root material for the next crop. Harvesting more than an acre plant realistically requires specialized harvesting machinery known as a puller or grubber.

After the flax plants have reached the appropriate stage of maturity for harvest, the next critical step is field retting. This process, lasting 1 to 3 weeks, involves exposing the harvested flax to natural conditions like dew and rain. Field retting relies on the community of soil microbes, including specific fungi and bacteria, to break down the lignin and pectin bonds that bind bast fibers to the outer bark and inner woody pith stem. “Assessing the ret” requires skilled judgment to know when microbial action has sufficiently loosened the bast fiber from surrounding tissue, without degrading it. Proper retting makes it easier to mechanically extract clean, high-quality flax fibers. The European Union no longer uses water retting, which involves submerging the stem in running water, or in large vats. Water retting requires large quantities of water and creates effluent which is a water pollution issue.

The climate conditions in Wisconsin, coupled with the crop’s minimal irrigation needs, make this a suitable region for cultivating flax for fiber production.

For more production related information, visit the websites of Iowa State University and North Dakota State University.

Research Status and Priorities

Because there is no flax fiber industry in Wisconsin, important research lacks funding. There are questions which need to be addressed regarding seed, best management practices, equipment, and developing markets. Wisconsin Linen Revival, a group of flax advocates, seeks to raise awareness of flax, assess its potential in Wisconsin, and create a commercial industry in the state. WLR has identified the following priority areas for breeding, research, and industry development.

Agronomic Research

Research optimal seeding density, harvest timing, fertility requirements, and crop rotation. Explore “Goldilocks maturity”, determining when fibers are immature enough for processing into high quality fiber yet mature enough for seed harvesting so that flax could be a dual commodity crop.

Breeding

There is an urgent need to develop seed strains which are adapted for the future Upper Midwest climate. Breeding priorities include optimal plant height, resistance to lodging, resistance to Fusarium and other diseases, and drought tolerance.

Equipment

To grow and process fiber flax at an industrial scale, there is a need to develop new mechanical harvesting equipment, explore sources of used harvesting and processing equipment, and develop mid-scale processing equipment.

Processing

The process of transforming fiber flax into linen involves several steps. Modern industrial processes involve variations and technological advancements in some of these steps. However, the general principles of retting, rippling, breaking, scutching, hackling, spinning, and weaving remain fundamental to the production of linen from fiber flax.

Harvesting: The flax plants are harvested when they reach maturity. The timing of the harvest is crucial, as it determines the quality and properties of the flax fibers. The plant is pulled from the ground by its roots, and laid in alignment on the ground in a thin layer as they are harvested.

Retting: After harvesting, the flax stems undergo retting, which is the process of breaking down the outer layers of the stem and separating the fibers from the woody core. There are two main types of retting: dew retting and water retting. Dew retting involves laying the flax stems on the ground and allowing them to be naturally exposed to moisture, dew, and microorganisms over a period of several weeks. Water retting involves immersing the flax stems in water, such as a pond or tank, to facilitate the decomposition of the outer layers by anaerobic microbes. Both methods result in dissolving the pectin that binds the fibers bundles to the inner and outer layers of the stem.

Rippling: In rippling, the stems are combed to separate the seed bolls from the stem.

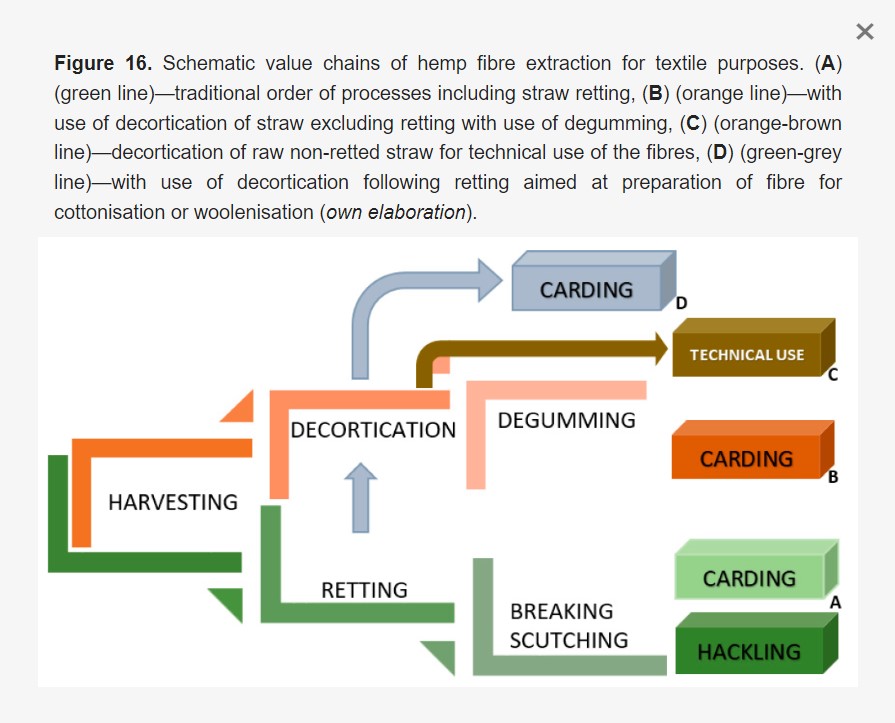

Breaking and Scutching OR Decorticating : Once dried, the flax straw is mechanically broken to remove the woody core from the fibers. This process is called breaking. The broken flax straw is then scutched, which involves scraping the straw to further separate the fibers from the remaining woody material. An alternative to microbial based retting is the mechanical process of decortication, which results in shorter fibers. Hemp plants often undergo decortication. See the diagram below for retting vs. decortication.

Hackling: The flax fibers are then hackled, which involves combing them through a series of ever finer metal teeth to remove any remaining impurities and to align the fibers in parallel strands. This process removes the shive and prepares the fibers for spinning.

Spinning: The hackled flax fibers are next ready for spinning into yarn or thread. The fibers are twisted together to form a continuous length of linen yarn. Keeping the fibers moist, while spinning, “wet spun”, yields a smoother, higher quality yarn. Retted fibers are longer and require long line spinning equipment. Decorticated fibers are shorter, which allows them to be spun on equipment designed to spin the shorter staple cotton fibers. Indeed, these shorter flax fibers are often referred to as “cottonized.” At this point the thread is ready for weaving, knitting and other applications.

Markets

There are multiple established market opportunities for high quality flax fiber at both small local and large global scale. In the short term, it will be a challenge to grow enough acreage in Wisconsin to support industrial processing infrastructure.

There is unmet demand for seed for fiber flax throughout North America, which is one of the first markets that Wisconsin production can satisfy, once best varieties have been identified and developed.

Supplying hand spinners with ready to spin sliver is a small but enthusiastic artisan-scale market. It’s well established that demand for natural textiles, including linen, is growing (see figures below). There is unmet market demand for flax fiber in North America, which can be developed by working with the community of designers of clothing and home goods who prefer to work with linen and the willing consumers eager to buy their wares.

Wisconsin can be a source for flax fibers for processing within the United States and export to European and Asian processing facilities. A similar arrangement is being developed by Fibrevolution in Oregon. Flax fiber grown organically in Wisconsin could be eligible for processing at a facility in Pennsylvania, being developed by PA Flax Project, which recently received a three year, million dollar Organic Market Development Grant, from the USDA. The existence of international standards for flax fiber, developed by USDA’s Agricultural Research Service, will facilitate the development of this product for international export markets.

Long line flax fiber is used for high end textiles. There is also a secondary market for mature fiber, known as tow, which results from breaking, scutching, hackling and combing, has been predominantly used for stuffing, paper and rougher textiles as well as many household uses. This lesser quality flax fiber can also be used in the manufacture of geotextiles used to reduce the level of dust and erosion at road, railway, construction and mine sites, as well as in horticultural applications to reduce or eliminate weed growth. There is an increasing growth of demand for flax fiber to replace fiberglass in plastic composites – flax fibers are generally cheaper, lighter in weight and impart more flexibility than fiberglass as well as taking less energy to manufacture. Lastly, shive, the innermost stiff part of the stem, is used for things such as animal bedding, insulation, and mulch. Importantly, demand is growing for new technologies that use shive and mature fiber as reinforcements in composite materials such as bio-plastics. There are potential markets to be developed for each of these fiber flax products.

Seeds

The availability of seed developed for fiber in North America is very limited. Imported seed is cost-prohibitive at a commercial scale and is not adapted to the Upper Midwest. Developing seed varieties adapted to this region is a priority. However, there are a few sources in the US for purchasing flax seed strains developed for fiber.

Resources and information

Read

Watch

Jennifer Green (Nova Scotia College of Art and Design)

Representative Chellie Pingree (D-ME-1), Co-Chair Sustainable Energy and Environment (SEEC) Climate and Agriculture Task Force

Heidi Barr and Emma de Long, Pennsylvania Flax Project Founders

Listen

In addition to the podcasts below, check out Weaving Voices Podcast, hosted by Fibershed Executive Director Rebecca Burgess, which tells the stories of our textile culture through a range of topics related to fibers.

More Resources

Alliance for European Flax-Linen & Hemp

Biolin Research Incorporated

Fibre Evolution

Iowa State University Extension and Outreach

North American Linen Association

North Dakota State University

PA Flax Project

Tap Root Fibre Lab

Wisconsin Linen Revival

Flax in the News

Members of Congress Launch First-Ever Slow Fashion Caucus to Curb Fast Fashion Pollution (6/27/2024)