Kernza Post-Harvest Processing Toolkit

Kernza® Post-Harvest Resource Toolkit

So you’ve planted your Kernza…now what? Unlike other grains, you can’t just take your Kernza to your nearest grain elevator and be done with it. There are a number of steps growers need to take between harvesting and transporting their grain off farm. Understanding best practices for post-harvest storage, handling and processing will ensure your grain maintains its quality throughout its storage life and meets the standards of prospective end-buyers. This toolkit provides resources to help growers understand these post-harvest processes and meet the requirements of their Kernza grower license agreement. Scroll down to find more information on the following topics:

Technical Assistance

The learning curve for beginning Kernza growers can be steep and the amount of information can quickly become overwhelming. In addition to the resources provided here, there are a number of people who can provide support to growers in the Upper Midwest. Growers in Wisconsin can contact any member of the WI Kernza Supply Chain Hub for help with production, post-harvest handling, processing and marketing considerations. Outside of Wisconsin, growers should contact staff at the University of Minnesota’s Forever Green Initiative or The Land Institute.

For more information on all things related to Kernza – including production, technical assistance, supply chain partners, product development, retailers, and much more – visit kernza.org and navigate to the Resources tab.

Kernza Identity Preserved Program

All licensed Kernza growers must follow the Identity Preserved Program (IPP) protocol. The IPP requires growers to report production and harvest data to The Land Institute for research and commercialization purposes. Make sure you are familiar with the protocol so that you keep appropriate records. Expect staff from The Land Institute to follow up with you at the end of the growing season to collect this data.

Kernza Grower Guide

This comprehensive grower guide is full of practical information on how to grow Kernza, from establishing your field to marketing your grain. See pages 39 and 40 for a primer on post-harvest handling and storage methods.

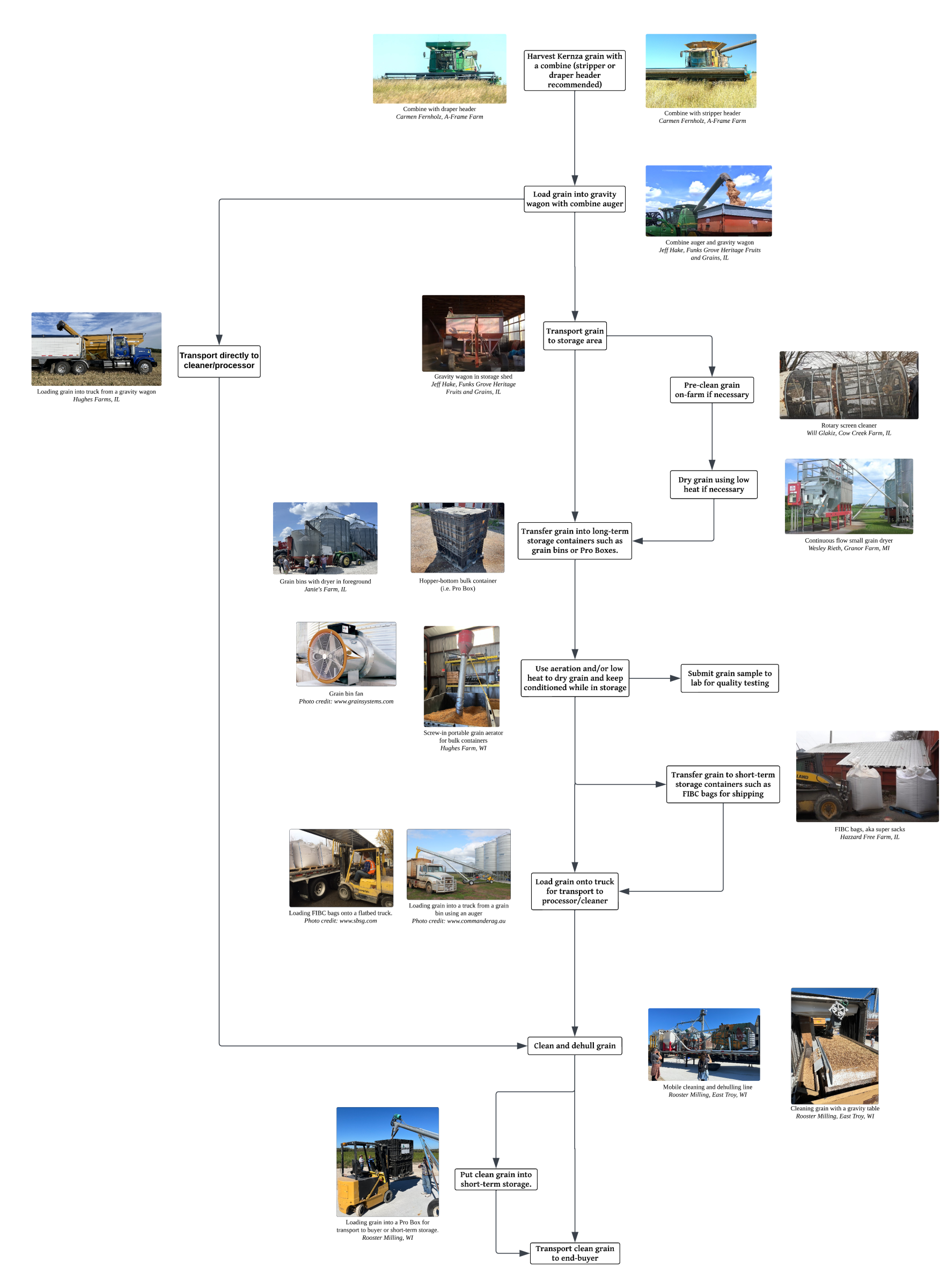

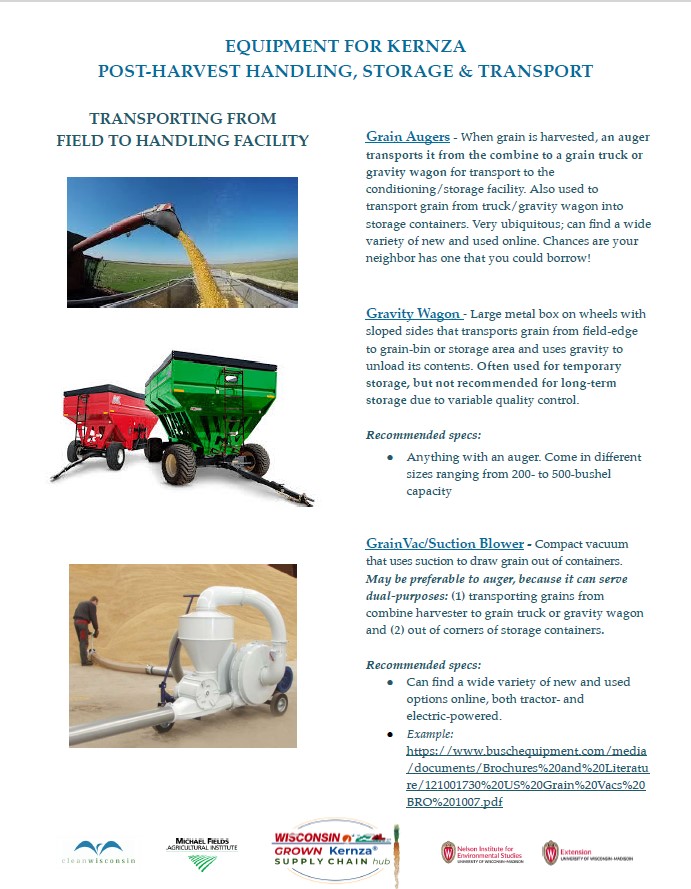

Equipment for Post-Harvest Handling, Storage, and Transport

Before harvesting your Kernza, make sure you have all the necessary equipment for storage and transport. Specific equipment needs will vary from grower to grower, depending upon scale, existing equipment and other factors. This document provides details on a range of equipment that growers will find useful.

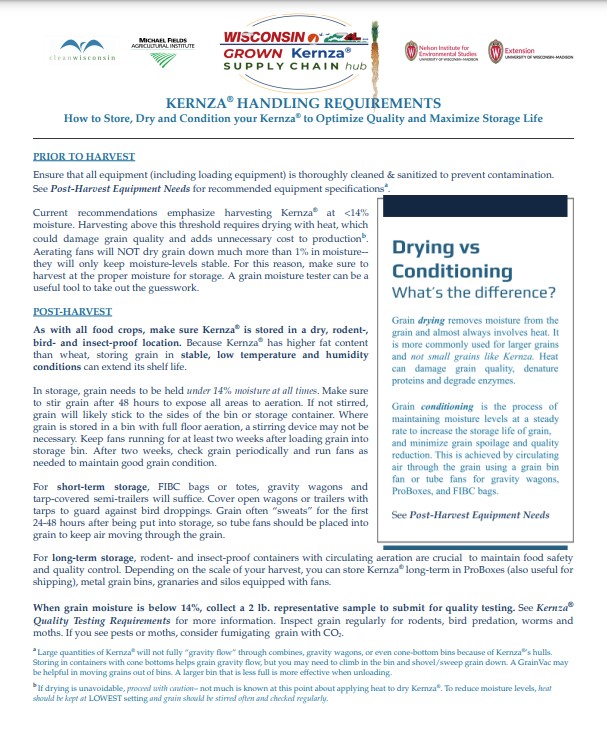

Kernza Handling and Storage Recommendations

Proper storage and handling of your grain is critical to maintaining its quality. Without the proper care and attention, all the grain you put so much effort into growing and harvesting could quickly spoil and lose its value. This publication will help growers understand the steps they need to take to maximize grain quality throughout its storage life.

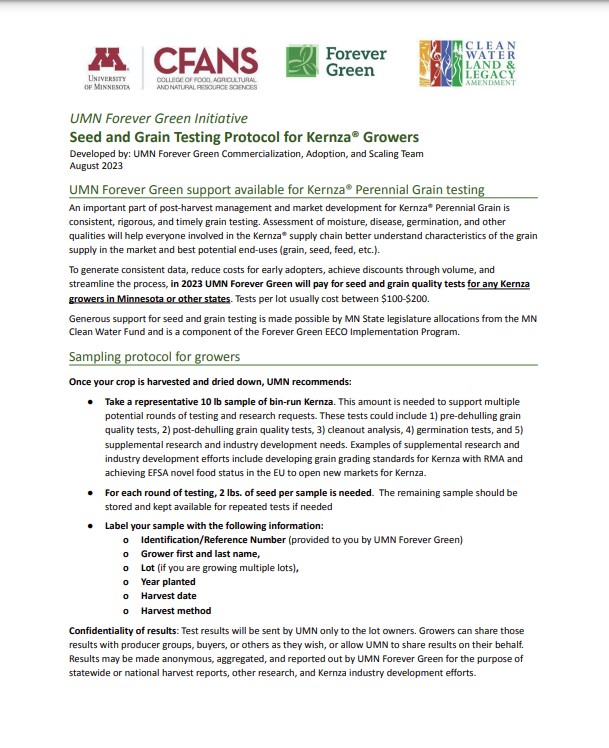

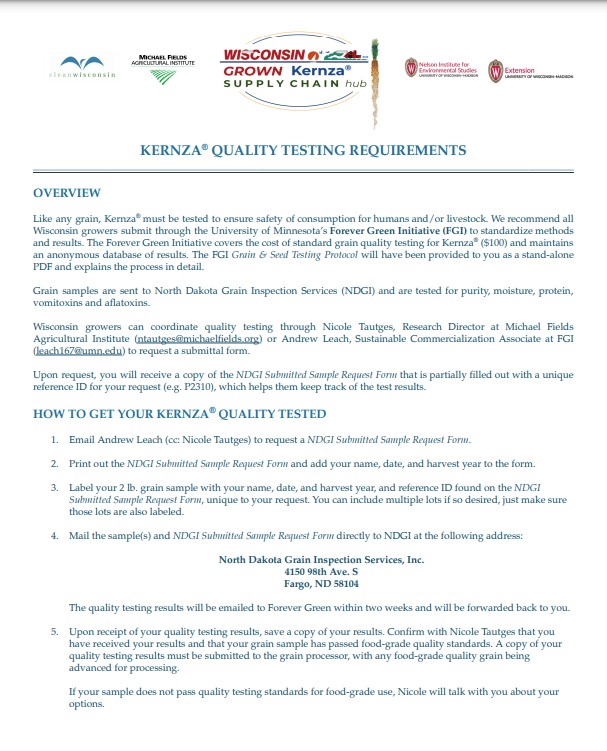

Grain Quality Testing

After your grain is in storage, it needs to be tested for certain quality parameters. The quality test ensures that the grain is safe for human consumption and meets the standards of end-buyers. Growers will need to submit samples of grain to a designated lab to test for purity, DON mycotoxin, moisture and protein. These tests are required by The Land Institute for growers to complete certification and sell their grain with the Kernza® trademark. The publications below help guide growers through this process.

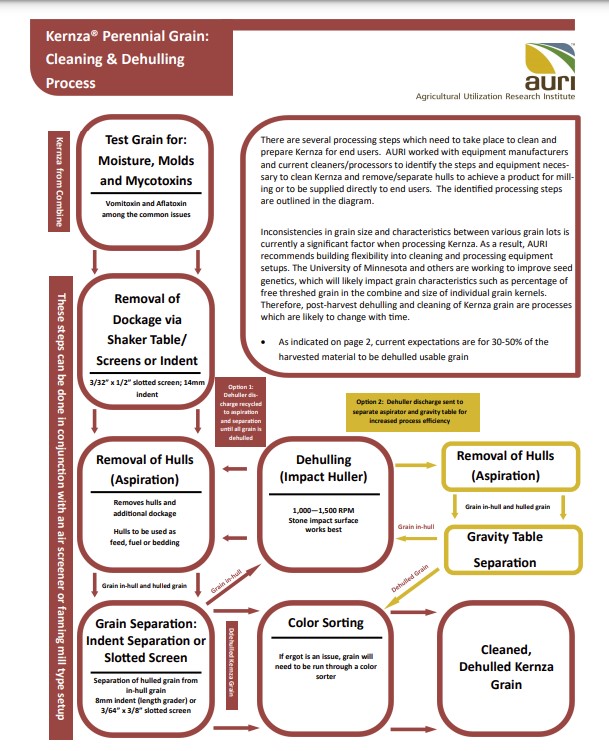

Cleaning and Dehulling

Kernza grain needs to be cleaned and dehulled before it’s ready for sale to an end-buyer. This is usually done by a custom processor with specialized equipment who has experience working with Kernza. This infographic shows the different steps involved in this process. It’s best for growers to reach out to their contacts at support organizations such as UW-Madison Extension, the Forever Green Initiative or The Land Institute to help them find Kernza processors.

This video walks growers through the different stages of cleaning and dehulling Kernza grain in a pilot lab at Agricultural Utilization Research Institute (AURI) in Minnesota. Growers can use this example to help develop their own processes and implement them on-farm. The second half of the video shows an on-farm pre-cleaning and dehulling line developed by one grower-member of the Perennial Promise Growers Cooperative (PPGC). This pre-cleaning and dehulling line helps clean dirty grain to the standards required by a commercial processor for final processing. This line may be available to other grower-members of the PPGC.

Additional Resources

Grain Buying Agreement

This Grain Buying Agreement is an example of a contract agreement between a grower and buyer and lists the expectations of each party. It can be used as a template and modified to meet specific needs.

LTL (Less-Than-Truckload) Freight Shipping

This document provides information on how to transport grain that doesn’t fill up a semi-trailer.

This work was made possible by the generous support of The Daybreak Fund and AFRI Sustainable Agricultural Systems Coordinated Agricultural Project (SAS-CAP) grant no. 2020-68012-31934 from the USDA National Institute of Food and Agriculture.

Any opinions, findings, conclusions, or recommendations expressed in these publications are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy.