Introduction

The use and adoption of technology in crop production continues to accelerate as new tools are introduced to the marketplace at relatively affordable prices. The options and applications for precision agriculture technology during the planting season are extensive. To better understand the options available and their potential benefits we must be familiar with them and how they work. These include boundary mapping, section and row control on planters, variable rate planting, adjustable planting depth, variable downforce, row cleaners, and closing wheels. The increased profitability from an investment in precision agriculture technology may come in several forms such as reduced waste, increased yield and increased efficiency.

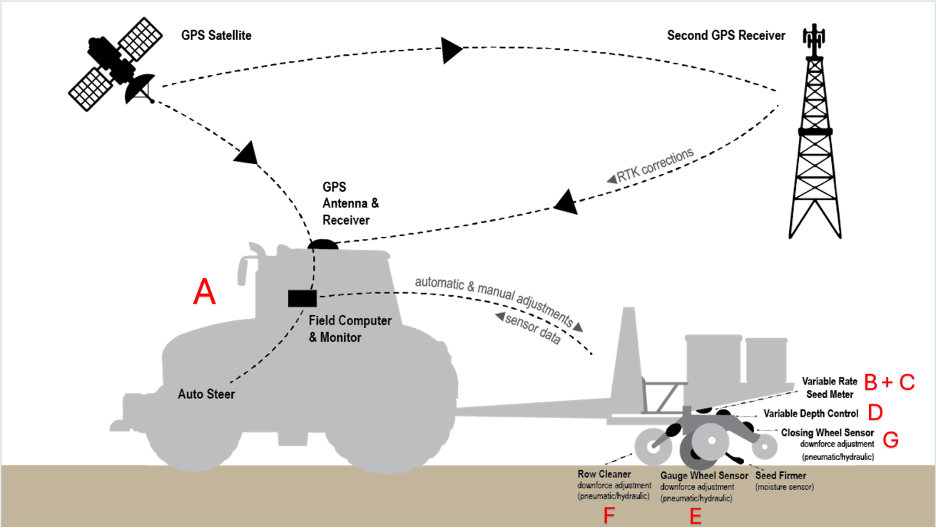

When thinking about the various technologies on the market, it may be difficult to understand the various technology and equipment setups needed to properly utilize precision agriculture technology. The diagram below (Figure 1) may help understand how the tractor technology communicates and the location of the physical equipment needs for each precision planting option discussed below.

Boundary Mapping

Field boundary mapping is the basis for all GPS-based field work. Field boundaries can be created in many ways from drawing on a satellite map to driving the edges of fields with a tractor or other vehicle. Driving the field edges, waterways, and other obstacles is usually more accurate and is the preferred method in most cases. With accurate field boundaries, you can set up a planter to shut off row-units over water runs or on field edges, AB lines can follow field edge curves, and autosteer can avoid mapped obstacles.

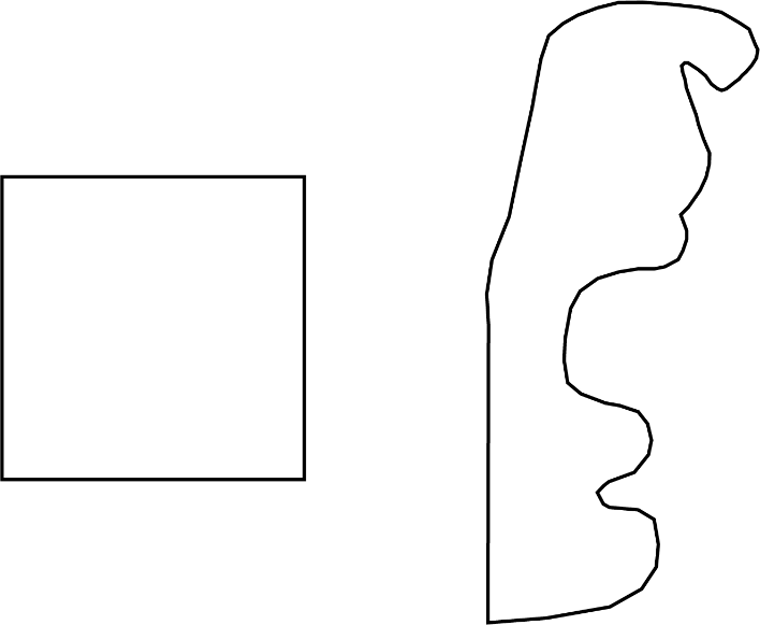

Calculating the perimeter-to-area ratio after boundary mapping is one way to determine whether a precision technology investment might be economical on your farm. The most return on investment with precision agriculture technology will come with automatic shutoffs of some kind that prevent overapplication of seed, fertilizer, and chemicals. Automatic shutoffs have a higher return on investment in fields with a higher perimeter-to-area ratio because they generally have more headlands and potential overlap than large square fields with a low perimeter-to-area ratio (Figure 2). This calculation must be done to compare fields of similar sizes.

There is one exception: this method is not well suited to evaluating long strips or contour strips, as they will have a high perimeter-to-area ratio; however if their width is consistent, they should have little potential overlap.

Right shape — perimeter: 4891 ft, area: 13 acres, ratio: 376

Figure 2: Comparison of fields the same size with different perimeter measurements and respective perimeter-to-area ratios.

Row Shutoffs

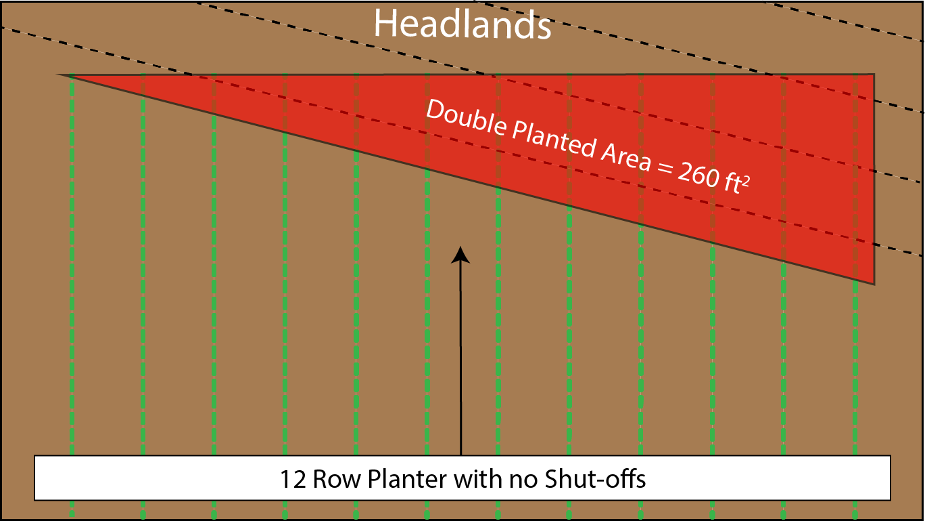

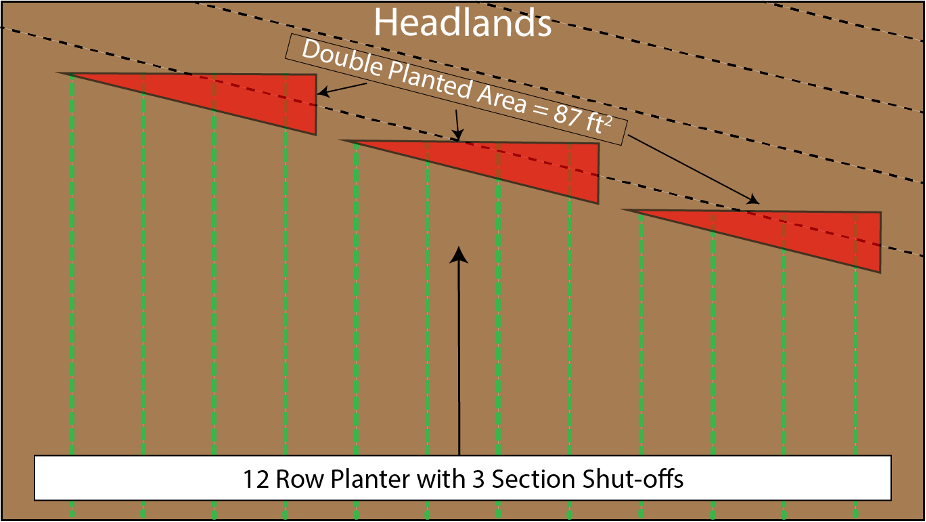

Row shutoffs are a precision agriculture technology that have a direct and measurable return on investment, especially in corn production. Row shutoffs prevent double planting, or planting seed in the same place twice.

Double planting reduces profit in two ways. When an area of the field, usually the headlands, gets double planted the plant population is twice the desired rate for the field in that spot. This was found to cause an average corn grain loss in that area of 17% with combined yield and harvest operations loss (Runge et al. 2014).

Double-planted areas in the headlands also result in double the seed expense for those areas. Double planting is often a bigger problem in odd-shaped fields and with larger planters and overplanting of soybeans is less of an economic or agronomic concern.

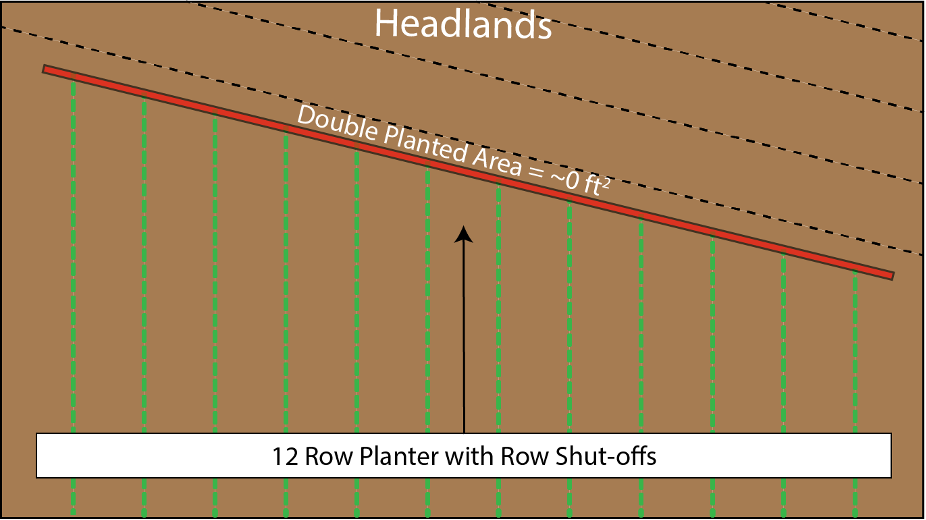

Row or section shutoffs reduce or eliminate double planting by automatically shutting off the row or section when it enters the headland; thus, preventing the yield loss and extra seed expense. There are several different types of row shutoffs. Row shutoffs may consist of pneumatic or electric clutches that either turn single rows or sections of rows on or off.

Alternatively, hydraulic drives may be used to run sections that can be turned on or off via electric solenoids. Electric drives on individual row-units are the most common on new planters and allow for individual rows to be shut off as well.

Variable Rate Seeding

Variable Rate Seeding (VRS) technology has the potential to increase farm productivity and profitability by allowing for the adjustment of seeding rates based on in-field variability.

From previous studies, we know that yield response is influenced by seeding rate, and other environmental factors such as soil type, position on the landscape, soil fertility, pest pressure, production history, and weather. So, the ability to adjust seed populations to reach the point of maximum yields based on field variability can improve crop productivity and profitability.

The use of VRS starts with understanding and identifying field variability that can be managed with different plant populations. These areas could be based on historical yields, soil properties, pest dynamics and topography. For example, soybean populations may be reduced in areas with high white mold pressure, but soybean seed populations in low production areas can be increased.

Once zones are identified, information on agronomic response to seeding rates can be used by an agronomist to create variable rate prescriptions. The ability to use customized seeding rates in different zones in the field could potentially result in higher yield and lower input cost. There may be considerable effort and specialized software needed to create zones, so it is important to have someone familiar with the technology to create these maps.

Automatic Planting Depth Adjustment

Automated or electronic planting depth adjustment is a relatively new technology. This technology allows the operator or the system to change the planting depth on-the-go while planting.

The advantage to this technology is apparent on fields with variable soil types causing variable depths to adequate moisture. Changing depth settings to account for different conditions across the field could be done manually by the operator; however, this would likely not be as effective as an automatic adjustment. Automatic adjustments can be made based on a prescription map or with a seed trench moisture sensor. Prescription maps could be based on underlying soil types or elevation to identify features like knolls throughout the field.

Seed trench moisture sensors are also very new technology and are designed to complement the adjustable planting depth system on a planter. When the soil is too dry, the integrated system can raise the gauge wheels and go as deep as it must to find soil moisture.

Variable Down Force

Downforce margin, also referred to as downforce or gauge wheel load, is an important planter component/setting that influences seeding depth. Ensuring that seeding depth is accurate across the field helps establish uniform germination and emergence and ultimately impact yield. The downforce margin setting allows you to set the amount of load carried on the gauge wheels at any given time.

There are three other ways in which downforce affects row-unit dynamics: maintaining ground contact, setting the soil structure, and establishing furrow structure.

Maintaining ground contact is important because if ground contact is reduced, it can be an indication that the planter is struggling to maintain consistent planting depth.

Downforce influences soil structure because the gauge wheels act as small rollers that force air pockets out and densify the soil, which ultimately sets the soil structure around the furrow. The soil structure around the furrow can impact root growth of the crop. When the roots grow into large air pockets their growth can be hindered and lead to uneven emergence.

Lastly, the downforce setting influences the furrow structure, or the “V” created in the ground for the seed needs to hold long enough for the closing system to come through and firmly pack the soil around the seed. If the furrow isn’t stable and starts to crumble, the soil may not provide adequate seed-to-soil contact, which could hinder crop emergence.

On traditional planter set-ups, downforce settings are highly variable and must be monitored manually as soil moisture conditions change throughout a field or from field to field. Newer precision agriculture technology systems have allowed for variable downforce capabilities with hydraulics for in-field adjustment of the set downforce based on the current field conditions.

To fully utilize this technology, it’s important to understand the soil type, moisture conditions, and compaction conditions in the field. Downforce can be adjusted by adding more weight in conditions where there may be heavy residue or compacted areas or by removing excess weight on the gauge wheels to prevent sidewall compaction.

Ultimately, having the capability to adjust to that variability can help ensure uniform planting depth is achieved which can prevent late emerging plants, compaction, and yield loss throughout the field or from field to field.

Row Cleaners

Row cleaners are an important consideration at planting time. The purpose of row cleaners is to only move residue that will prohibit the disc openers from placing seed at the proper planting depth. This can be an important tool in ensuring proper planting and reducing the risk of yield loss from seed placed at incorrect seeding depths.

Row cleaners are not new planting tools, but recent updates in row cleaner design have allowed for more integration with precision agriculture technology. Newer row cleaners on the market have changed how they are attached to the planter unit, allowing for the row cleaners to be attached to the planter frame itself. This alteration reduces the impacts row cleaners have on downforce and overall row-unit ride.

There is also a precision component to the row cleaners. Certain types of newer row cleaners have independent down pressure and tine depth adjustment capabilities that allow the operator to adjust pressure to change tine depth from the tractor cab. These innovative alterations will aid in improving row cleaning capabilities, allowing for proper seeding depth to be achieved in high residue and no-till systems which can improve emergence and maximize yield potential.

Closing Wheels

Planter closing wheels and closing systems have been gaining interest from farmers due to the increase in no-till acres and aftermarket options. One of the main concerns in no-till planting and conventional planting to a lesser degree, is sidewall compaction in the seed trench.

Sidewall compaction is the term used to define the tendency of the seed trench walls to become compacted, smeared, and relatively impenetrable to roots. This can reduce emergence and lateral root growth resulting in less nutrient and water uptake causing reduced yields and increased lodging.

Aftermarket closing wheels can help alleviate sidewall compaction and increase emergence compared to stock or traditional closing wheels set up for conventional tillage. A study from Dr. Brian Luck at UW–Madison compared three aftermarket closing wheels to a stock rubber closing wheel. Dr. Luck and colleagues found all the aftermarket closing wheels increase emergence in a no-till system but did not find one specific aftermarket option to be better than another. It is likely that soil moisture, texture, and other field conditions play a significant role in which type of closing wheel best suits a specific operation.

Stock and aftermarket two-stage closing systems are also available. These offer potential advantages such as reduced seed trench compaction and the ability to apply fertilizer behind closing discs.

Final Thoughts

When deciding which technologies to implement, consider all your options. Each of the technologies discussed above can have positive benefits, but depending on your operation, some of these technologies may be more beneficial than others. Consider the aftermarket solutions compatible with your current equipment and explore how these upgrades could help improve your farm’s efficiency and profitability.

Highlights

- Accurate boundary mapping is critical to implementing any precision agriculture practice, including implementation of planter technology.

- Utilizing the perimeter-to-area ratio of your fields can provide insight into the viability of implementing precision agriculture technology on your farm.

- Row shutoffs are effective at minimizing areas where double planting occurs, maintaining yield potential and saving seed.

- Variable rate seeding can be used to optimize plant populations where variability occurs in fields. Increasing or decreasing populations can maintain yield, save seed, and maximize profitability.

- Automatic planting depth control allows for on-the-go planting depth changes. Ensuring proper planting depth benefits plant emergence.

- Active row-unit down force maintains proper row-unit dynamics while planting, so proper planting depth and seed-to-soil contact is achieved.

- Row cleaners, in high-residue or no-till conditions, ensure that the disc openers are interacting with the soil properly and that the gauge wheels are contacting soil so that proper planting depth and seed-to-soil contact can be achieved.

- Closing wheels cover the seed in the furrow. Aftermarket closing wheels can help break sidewall compaction caused by the disc openers and help maintain emergence in variable planting conditions.