Weed control is evolving—and Dr. Jed Colquhoun is here to show how robotics, AI, and automation are reshaping the future of agriculture. In this forward-looking workshop, Dr. Colquhoun explores the rapid rise of ag robotics and how tools like laser weeders and precision sprayers are already transforming weed management in high-value specialty crops.

This talk was given at the second annual Wisconsin Extension Weed Management Workshop on Sept. 11, 2025.

With real-world data, field trials, and side-by-side comparisons, Dr. Colquhoun breaks down the practical challenges, economic realities, and agronomic benefits of integrating robotic weeders like the Carbon Robotics Laser Weeder and EcoRobotics ARA. From reducing herbicide use and labor costs to boosting yield and crop quality, this session is packed with insights for growers, researchers, and ag tech enthusiasts alike.

Dr. Colquhoun discusses:

- Why robotics are gaining traction in weed management

- Herbicide resistance and labor shortages

- Laser weeding technology and sub-millimeter accuracy

- Spot spraying with AI and smart algorithms

- Yield, ROI, and crop quality comparisons

- The future of automation in row crops and beyond

Transcript

0:05

Great.

0:05

Thanks very much, Rod Rodrigo, and good afternoon to everybody.

0:09

Thanks for being here this afternoon.

0:12

I’m going to start my presentation with just a little bit of context.

0:17

As recently as three years ago, when I would stand up in front of an audience like this and talk about things like Laser Wedding, I would see a collective eye roll go across the audience.

0:28

I think the general consensus if I were to read those minds would be #1 I’m watching way too many science fiction movies and #2 that guy needs a check up from the neck up.

0:40

It was crazy talk at that time.

0:42

Fast forward just three years and that is the reality on the screen in front of you today.

0:48

Not only is it the reality, but as I’m about to show you, it’s evolving at a pace like nothing I’ve seen in agriculture before.

0:57

And I’ll show you.

0:57

I don’t think that’s overstated.

1:00

In fact, if you look at the combination of AI, remote sensing, robotics, automation, novel control tools, I would say that we are right at the doorstep of the next agricultural revolution.

1:13

So thank you, young people that are in the audience today.

1:16

Thank you for being here.

1:18

You’re in the driver’s seat of that next revolution.

1:21

And I’m going to give you a little foreshadowing into what that looks like in my specialty crop world.

1:26

As Rodrigo mentioned, I’m going to talk about some of the main questions that we got.

1:32

There’s a lot out there.

1:33

You’ve seen a lot of technology today.

1:36

Things are changing rapidly.

1:38

We’re also in that sifting and winnowing stages of a revolution.

1:42

How do we know what matters, What’s practical on a farm?

1:45

I’m a realist.

1:47

How do we get to the point where we can apply these tools but still have profitable agriculture?

1:53

So here are the questions we’ll talk about today.

1:55

What challenges do farmers want to overcome with robotics and automation?

2:00

There’s a lot being sold out there.

2:02

Some of it’s applicable, some of it is not.

2:04

What technology do we need to achieve those goals and kind of general terms?

2:09

And then we’ll hone in a little bit and I’ll show you some of the recent research we’ve been conducting on the status of robotics and automation for weed management in particular.

2:19

And finally, I’ll foreshadow where this is all going in the next agricultural revolution.

2:26

Now before we go there, though, let’s get the eye roll done with.

2:29

And I want to talk to the naysayers directly right from the beginning.

2:33

I have some concessions to make here and I own them.

2:36

I’m a realist.

2:37

These tools are expensive, there’s no doubt about it.

2:40

This is more expensive than your your old tractor and cultivator.

2:45

And because of that they have their first application oftentimes as Rodrigo mentioned in the specialty crops, these tools operate slower and they covered less ground than large spray rigs at this point in time.

2:59

That is true.

3:00

That is changing quickly as I’m going to show you in a minute.

3:03

Therefore, their first adoption has been primarily as you heard from some of the the exhibitors today in these high value specialty crops, particularly where herbicides are applied often as I’ll show you where they cause injury and where hand wedding is costly if it is even available.

3:22

In a lot of cases it’s not even available for the folks that I work with.

3:26

But with all that said, this technology is changing at a breakneck pace and I’m going to show you an example on the next slide.

3:34

The example I have here is going to take us back in time.

3:38

That’s the first commercial cell phone, kids, you probably don’t recognize that there’s no screen on it.

3:45

That’s a Daktronics for a Motorola from 1984.

3:48

Weighed 2 1/2 lbs.

3:50

It could hold a charge for 30 minutes.

3:52

In today’s dollar.

3:53

It cost over $10,000.

3:56

Raise your hand if you don’t have a computer in your back pocket today.

4:00

I don’t see any hands.

4:02

That’s the stage where we’re at with the type of technology that we’re sharing with you today, and that’s the pace at which it’s changing.

4:11

Here’s the example of the evolution with the tool that I have my most experience with.

4:16

In this case, this is the laser weeder from Carbon Robotics, and I’ll show you more details about it.

4:22

But here’s the tool that we got a year ago.

4:24

This is a generation one laser weeder.

4:27

It weighs 12,300 lbs.

4:30

It’s on tracks.

4:31

It covers 20 feet at that case.

4:35

This is what happened in a year.

4:37

This is the tool they sell this year.

4:39

That’s a carbon dioxide laser.

4:41

This is a diode laser.

4:43

It’s more efficient.

4:44

It operates with less energy and it ends up with a tool that’s 40 feet wide and weighs the same as the tool we got a year ago.

4:53

That’s how fast this has evolved and there are more coming.

4:55

They have a 60 foot version available if somebody I really wanted to get into it.

5:00

But the new tools and modules, it’s not a 20 foot wide, you can have a six foot wide one up to in Northeast Iowa, there’s a 40 foot one operating now.

5:10

So that’s the type of evolution that we see in change in coverage of acreage and applicability, most important expensive portion in this marketplace right now.

5:23

That’s what drove down your cell phone price.

5:26

It’s going to happen here also.

5:29

So the current challenges in weed management that could be addressed by robotics.

5:33

This is somewhat preaching to the choir and we’re short on time.

5:37

So I’m going to keep this really concise.

5:39

Herbicide resistance is out of control.

5:41

I’ll give you an example.

5:43

In the lot of the specialty crops that I work with, we have weeds that have resistance to more herbicide sites of action than we have registered in the crop.

5:54

We have water hemp with 5, 6, 7 herbicide sites of action resistance.

5:59

Some of the crops I work with like carrots, we use two herbicide sites of action.

6:03

Hard to overcome new herbicide sites of action are few and far between despite our best efforts.

6:09

Really the last commercialization of heavily adopted herbicides would be 1988, the HPPD inhibitors Laudis, Impact, Callisto, etcetera, 1988.

6:20

There are people in this room that weren’t alive the last time we got a herbicide site of action registered regulations going to continue to limit use.

6:29

And I look at folks like Greg Dahl and Steve Hoffman.

6:32

We’ve been spending a lot of time figuring out how to comply with the Endangered Species Act, limitations on pesticide use, EPA, The way you can reduce your buffer around a threatened or endangered species the most is to use less of a chemical.

6:48

Their tool uses 95% less.

6:51

You won’t have a buffer.

6:53

You will be in compliance in that case.

6:56

And specialty crops, existing herbicide programs can be injurious and reduce high value crop yield and quality.

7:03

That’s why they got adopted first.

7:05

What we were doing didn’t work and it caused injury and I’m going to show you that.

7:09

And finally, where hand wedding labor availability is limited, I know most of you don’t deal with that, but I can tell you from West Coast partners that I work with and this type of work, one of them pays 65,000 a month in hand wedding labor, 135 hand weeders, that tool on the previous slide, 2 operators on 10 hour shifts.

7:32

And, and it’s not a matter of job replacement.

7:34

There are other things they do on the farm, but it’s more productive than holding a hoe.

7:40

It’s a lot easier to watch Netflix on an iPad while a tractor runs by itself.

7:45

And they love it.

7:46

As a matter of fact, one of them told me recently that he had to change jobs because he ran out of things to watch on Netflix.

7:53

We got HBO Max, you know, there’s all sorts of things we could do.

7:56

Yeah.

7:58

So what technology is needed to achieve these goals?

8:01

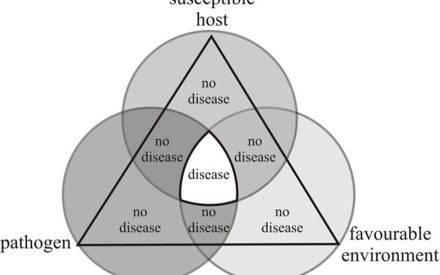

Again, we’ll hit this quickly, but there are three key things that changed in those three years since I was watching the science fiction movies #1 detection, accurate, high resolution imaging, and then doing it in real time as a machine flies across the field.

8:18

Interpretation.

8:19

That is the key piece, using artificial intelligence or AI to interpret a crop from a weed and even with some of the tools I’ll share with you, find the growing points on the weed as that machine goes across the field with sub millimeter accuracy control.

8:36

Use a novel control tool to manage weeds without crop damage.

8:40

I’m not going to share with you a lot on the novel cultivators that have been around for a while.

8:45

They have a great place like thinning leafy greens with a stout cultivator out West.

8:50

That’s great, but you can’t use a cultivator when soil’s wet, no matter what AI you have on board.

8:56

Some things never change in farming.

8:58

So we’ll talk about the novel tools in particular.

9:02

And then the bonus is to automate all these processes so that we have fewer people needed in the field to do it because we have fewer people farming than we have ever had in our country’s history.

9:15

So let’s take just a quick tour.

9:17

Spot sprayers or many around.

9:18

Eco Robotics has a great tool on hand today.

9:21

This is the Verdant Robotics piece you saw earlier.

9:25

Basically cameras sensing weeds from crops or in this case, thinning leafy greens in California and then using these micro turret sprayers to give just a little blast to spray.

9:38

Similar concept really to the Eco Robotics ARA.

9:41

They have a different way of delivering through many more nozzles, but the seed and spray type technology, you can see with the AG spray dye where it’s hit these weeds and the and the leafy greens in this case.

9:55

So we’ve talked a lot about that.

9:56

This is the stout smart cultivator again, used for thinning leafy greens out West as well as hand wedding around here.

10:05

I’ve not focused on using this technology simply because of those limitations on what soils.

10:11

Getting behind two or three days is a disaster.

10:14

So that’s not something that’s been really a focus of of mine in this case.

10:19

But it has a aplicability in some of the West Coast crops where water, it really is controlled as an input via irrigation.

10:26

We don’t get rainfall during that time of year.

10:31

And then the third one which I’ll talk a lot about are the laser weeders.

10:34

Again, this area of rapid evolution and technology, this is a carbon robotics laser weeder.

10:41

This particular unit that we use in our research has 30 carbon dioxide lasers that are informed by 42 high resolution cameras and an algorithm.

10:54

They’re all interacting with Starlink satellite system.

11:00

So every time the tool is operated across the globe, it learns something and takes images to feed those algorithms.

11:07

And every time somebody operates, it updates all the machines that are involved.

11:13

So for example, in our onion work in Wisconsin, one day we showed up in the machine had almost doubled in pace and we were wondering what happened.

11:22

Well, there’s a Texas onion grower that’s six of them, and he ran them all night.

11:26

And it had learned a lot from what it saw in that and applied it to our machine, also updated the algorithms.

11:34

And again, that’s a generation one tool.

11:36

They now have this generation 2 tool with diode lasers and a modular fashion up to 40 feet wide in commercial use right now.

11:45

And the other advance that they made in the past year, which is a little bit scary.

11:49

But it was one of the odd, oddest job descriptions I’ve ever seen.

11:53

And it was looking for somebody who’s good at gaming and likes staying up all night.

11:58

Why?

11:59

You can have a remote operating contract with this company and they’ll drive it from Richland, WA for you.

12:05

So you can watch Netflix at home.

12:08

Now you don’t have to sit in that cab, but obviously it’s a contracted service that’s paid for should you so choose.

12:15

But that’s the next step, automate these tools and a lot of companies are working on that.

12:21

So I’m just going to give you one example, and I acknowledge these are in onions.

12:25

Onions are super high value.

12:27

They’re niche crop.

12:29

It’s very different than corn and soybeans.

12:31

Think of this as a crystal ball to what your future might look like in this evolution in the corn soy row crop world.

12:39

So in this research, I’ll share with you, this was we just finished harvesting.

12:42

I, I may actually still smell like onions, but we’re building from the laser weeder optimizations optimization studies we did in 2024.

12:52

This isn’t a large scale replicated plot situation.

12:55

It’s on a commercial farm in Palmyra.

12:57

These are not small plots.

12:59

They’re half a mile long roughly.

13:02

So very large plots on a commercial farm and we’re looking at just four simple treatments, A conventional grower, standard herbicide program.

13:11

They have to hit these things six times during the season to be able to get some weed control.

13:17

Laser weeder 4 times, the Ecorobotics ARA that you’ll see and I’ve heard about four times.

13:23

And then we put the two together and this in this integration, we’re looking at how they play together to maybe optimize control.

13:31

These are not done organically and onions you simply couldn’t do that is you’ll see what an onion looks like as it comes out of the ground.

13:37

You can’t get behind no matter what.

13:40

So we start with a pre herbicide application, try to get the onion out of the ground, which takes about 3 weeks and and give it some residual weed control, some advantage.

13:50

And then we come back and, and all these treatments, including in a residual herbicide application on 6 leaf onions.

13:59

And because that’s roughly when we can’t drive in the field anymore and we need to be able to extend that residual control through onion harvest.

14:07

This is a long season.

14:09

To give you some perspective on that, these onions were planted in April.

14:13

They finally formed a canopy on around 4th of July takes a long time.

14:18

This is a knee high by 4th of July or chest eye, you’re lucky if you can get 8 inches on them in a few months.

14:25

So we need that residual herbicide to be integrated with these other options.

14:31

I’m a visual learner.

14:32

I’m going to jump and show you right what that looks like.

14:36

This is our herbicide onions, a lot of water, hemp, a lot of pigweed.

14:42

The barley is the dead cover crop in the middle.

14:44

That’s for wind erosion control.

14:46

This is on a muck soil.

14:48

So that’s our herbicide standard in that case.

14:50

That’s six herbicide applications and, and basically every week until they form a a canopy.

14:57

After they emerge, you can see a lot of escapes of the water hemp that would be hand weeded out basically by a hand weeding crew.

15:06

This is the laser weeder plot.

15:08

2 differences here.

15:09

The onions are about 6 inches taller.

15:12

There are no weeds.

15:14

Granted, it’s four laser weedings.

15:16

That thing ran 24 hours a day for about 11 days at one point to cover all the commercial acreage.

15:22

It’s not it’s it, it’s slow, it’s time consuming, but it does work.

15:27

It’s very, very effective and you can see we have less herbicide injury.

15:31

In that case.

15:33

The Eco Robotics, again, you don’t see the crop injury at all.

15:37

You do see a few weed escapes.

15:39

And that’s one where over the next year we’ve talked about improving that algorithm to be able to get on the onions even earlier.

15:46

Because in our ideal world, what we would like to do is run the Eco Robotics first because it goes much faster than the laser weeder, covers a lot more ground, and then use the laser weeder just for clean up.

15:58

And by doing that, we would also speed up the laser weeder.

16:02

When we’re doing the laser weeder alone, it was shooting up to 1,000,000 weeds per acre, a million weeds per acre.

16:10

Doing that, we’d like to get that down to more like 200,000 weeds per acre by using the Eco Robotics first and speed that whole operation up.

16:20

And then this is a combination of the two.

16:22

And that piece I want to highlight here is a yellow nutsedge.

16:25

We intentionally did not target the yellow nutsedge because it slowed everything down too much.

16:30

So you still need a little hand wedding, but it’s a lot easier to go on a 450 acre field and say just pull the nutsedge, I’ll take care of the rest, then spend the next week here in this field, hand wedding, everything.

16:43

But you see less herbicide injury again in this situation.

16:46

And other than the nutsedge, it’s clean as a whistle.

16:50

So there are some advantages certainly to integrating the two.

16:53

And again, with advances in the algorithms over time, we look to be able to use these tools even earlier.

17:02

This is what it looks like as far as the competitive advantage.

17:05

Remember our herbicide standard on the right hand side of both of these, they’ve been sprayed 6 times with some pretty injurious herbicides.

17:13

You have to do that, otherwise you lose the crop to weeds.

17:16

This is where we use the laser weeder alone.

17:19

This isn’t even close to our yield at that stage, but you can see mid season quite a growth advantage by reducing that herbicide injury where we’re laser wedding alone.

17:32

So cutting to the chase as far as hand wedding time, again, this is critical, brings back bad memories because that’s me doing this.

17:42

So this is a herbicide standard, laser weeder alone, eco robotics alone and then combining them too.

17:49

And you can see this year, because we were got on a little late on the onions with eco robotics alone, we did have some hand wedding in there.

17:57

But when we combine it with the laser wedding, it’s very low compared to our herbicide standard.

18:03

These are minutes per hectare in this case, but just looking at the relative differences, we’re able to drastically reduce our hand wedding with either the laser wedding alone or when we combine it with the eco robotics.

18:18

And that’s a really critical piece.

18:20

It’s hard to find hand labor and it’s extremely expensive.

18:24

Let’s cut to the chase and talk yield and onion growth.

18:28

We don’t see much difference in stand in this case.

18:32

There are some trends towards more onion stand where we’re using these novel tools.

18:37

Why is that critical in onions?

18:39

You may not think of it.

18:40

I know corn seeds expensive too.

18:42

Onion seed per acre is $1100.00 an acre.

18:46

Before you put the crop in the ground.

18:48

You have $1100 per acre in this.

18:51

But we do see enhanced growth.

18:53

We see more onion leaves.

18:54

Why are onion leaves important?

18:56

They form the rings.

18:57

If you’re a ring grower, you get paid per ring of onions.

19:01

That’s how onion rings are made.

19:03

So more leaves are important and more rings and we get more rings where we’re using these novel tools versus the herbicide standard.

19:12

And then finally, let’s go to the end here.

19:14

That seed’s expensive.

19:15

You want the all to last to the end and we want bulb yield.

19:19

This is the part that’s just amazing to me.

19:21

That’s the herbicide standard.

19:23

Here’s where we’re using the novel tools.

19:25

We have up to a 31% yield increase.

19:29

The grower has run out of storage for onions.

19:33

He’s selling them to his competitor at this stage because the yield is so high and the bulbs are large.

19:40

So there’s actually $1.50 to $1.70 per 100 weight per 100 LB bonus to having larger onions in the bag.

19:48

And they’re getting that right now.

19:49

So you take 450 acres and what we’re producing on that, that’s a $500,000 bonus from doing that.

19:57

So it pays for itself.

19:59

It’s a specialty crop.

20:00

I get it.

20:00

It’s not corn, not not soybeans.

20:03

Well aware.

20:04

So positives, the laser weeder, sub millimeter accuracy.

20:08

I’ll drive that home with a picture.

20:10

Rapid and responsive algorithm adaptations.

20:13

We can text them.

20:13

They respond usually within a few minutes.

20:16

I’ll give you 1 great example.

20:18

One day the wind was blowing hard and it was blowing the onions over and the laser weeder was.

20:23

Causing what we call crossfire hitting the onions trying to get to the weeds.

20:27

So we texted them in 5 minutes and updated the algorithm to correct for the lean of the onion in the in the field.

20:36

So rapid response can be used really early in the crop season because the algorithms are super refined.

20:43

And with that we get nearly 100% weed control, almost no hand wedding as you saw the yield increases can be substantial.

20:52

I’ll say they can be moderated if we get disease or insect pressure.

20:56

That’s the averager of all things and it can slow down this progress and they can now be remotely operated for a price.

21:03

Obviously negatives, no residual weed control.

21:07

You’re not putting on a herbicide.

21:08

What you hit today doesn’t keep anything from germinating tomorrow.

21:12

It’s slow, it’s slow.

21:14

It’s a much slower than a lot of other technologies, but it’s increasing.

21:18

It’s doubled during the season even and the upfront cost is high.

21:22

That original 20 footer was 1.4 million.

21:26

Now they’re much lower.

21:27

They could come down already and there’s competition we know in that marketplace.

21:32

But the grower that I originally started with, we have a few of these tools in the state now.

21:37

The grower that I originally worked with, we penciled out A7 year return on investment originally, and it paid for itself in a year and a half.

21:47

So it moved quickly.

21:48

Once we get that yield increase in the size and quality bonuses.

21:53

Here’s the laser weeder accuracy to put onions in perspective.

21:56

I should have put a penny here or something.

21:58

That’s the Catalean that dies off first.

22:00

Onion leaf.

22:01

That entire plant’s about like this.

22:04

That’s a purse lane resting against it, and it got lasered against the onion without hitting it.

22:10

That’s how accurate this thing is as it rolls across the field, shooting up to a million of those per acre.

22:18

The Eco Robotics significant herbicide use reduction.

22:21

We heard that 95% in this case, which is amazing, operates much faster as we heard rolls through the field and our grower loves it.

22:30

As a matter of fact, one night he called me.

22:32

He was huffing and puffing with the laserweeder.

22:34

A lot of times he’ll get out because you get bored and just go walk behind it for a while.

22:40

It operates a lot faster.

22:41

He’s huffing and puffing.

22:42

I said what’s going on?

22:42

He said, I’m running behind it.

22:45

You can barely keep up.

22:46

So can be used to target specific hard to control weed species and that’s where we intend to use it.

22:52

Let’s get the really tough ones out of the way with it.

22:55

Again, no broadcast residual control, but you could have a residual herbicide, but you’re you’re spotting it on the field.

23:01

It can’t be used in its current configuration or algorithm as early, but we’re hoping that changes so we can get the batting order in the other direction.

23:10

Ecorobotics first, later weeder second, works close to the crop.

23:16

You know, we saw a few of those pigweed escapes and one piece that’s already come up today.

23:21

You’ve already asked the question.

23:23

The growers that I work with, with this tool in particular ask, well, now I can put anything in the tank, right?

23:29

Because I’m not spraying the crop.

23:30

Now the field’s considered the crop.

23:33

You can’t just say, well, I’m going to spot spray, so anything goes.

23:36

The first call I got was, oh, great, now I can use atrazine on broccoli.

23:43

Good luck rotating next year.

23:45

So, but several efforts are underway to automate these large scale tool carriers.

23:51

Just to kind of clean this up here.

23:53

This is from the show out in the West Coast.

23:56

That’ll go on in a few weeks.

23:58

And they’re operators and inventors of all sorts of automation.

24:03

This one I found particularly interesting.

24:05

The gentleman that invented this, his back story is in he inherited a vineyard in California, but he was an engineer and he had trouble finding people to work on the farm.

24:16

So he built these technologies to mow, spray, drive around his harvest wagons and such.

24:22

No drivers.

24:23

It’s now paired with Kubota, his automated driving equipment.

24:27

Again, it’s evolving quickly.

24:29

And he was sitting there on his iPad watching his Vineyard run, you know, a couple hours away, which was cool.

24:36

So it’s changing very, very quickly.

24:39

And it’s independent of scale.

24:40

This is a Swarmbot tool carrier carrying a spray boom.

24:44

There are a lot of these around.

24:45

Also the boom’s folded up here just because this is at a Yolo County fairgrounds here, but obviously no operator on here is there.

24:54

And there’s a lot of this going on as you know to automate this equipment, a lot of rapid evolution beyond the, the, the novel control tools to the autonomous vehicles and it’s it’s scale independent.

25:09

A lot of our smaller growers will say, Jed, I’ll never be able to afford that.

25:13

They’re very small tools of all sorts in the same range.

25:18

Is there a matter of fact, even in the laser weeder world, there’s now somebody who’s developed a laser weeder about the size of that podium.

25:27

You can pick it up and carry it around.

25:29

Just don’t put your hand under it.

25:30

You’ll probably lose it, but you can move it around easily and it’s made for these small scale farms to laser weed in that setting.

25:39

So where do they best fit?

25:40

Now?

25:40

Again, owning the reality of this where labor availability and costs limit production, where the weed management tools are limited, where a sub lethal herbicide injury impacts crop yield and quality and where that crop value is high enough to pay for a tool like this.

25:59

Is it evolving quickly?

26:00

Yes.

26:01

It’s just amazing they’re going to advance rapidly.

26:04

There’s competition in the marketplace.

26:06

When that happens, like any other free market, we would anticipate A reduced cost and the best player will win.

26:13

And our primary focus is really to find ways to increase the implement coverage and speed without compromising weed control.

26:20

So how do we integrate residual herbicides, both of these great tools that I shared with you to hit that yield gain while keeping it realistic for the farmers and profitable.

26:32

So that’s what I have for you today.

26:34

I realize it’s very different than the corn and soy world, but again, think of this as kind of foreshadowing to the next few years as we see these tools expand in size and ground coverage.

26:47

With that, I’d be happy to take any questions you might have.

26:50

Hopefully caught you up a little bit there.

26:51

Rodrigo

26:52

Yeah, yes, Sir.

26:59

Does it kill the root system or just the top?

27:02

I’ll get you in.

27:03

I no, it’s fine.

27:04

Does it kill the root system or just the tops of it?

27:06

Great question.

27:08

I I’m assuming you’re talking the laser weeder.

27:11

So the laser weeder shoots growing points.

27:14

So when purse lane was getting larger that would have 5 or 6 growing points.

27:18

It didn’t smoke the whole plant, it only hit the growing points and that was enough to kill an annual weed.

27:25

When it got to a nut’s edge, honestly, we shut it off on the nut’s edge and let the hand weeding crews hit it because what it does is it triangulates multiple lasers at one time towards the nutsedge and it slows the machine down too much and it doesn’t control the control the root system.

27:43

No, it’s not like when we were doing the electrocution for weed control.

27:48

So we just skip it and you got it.

27:49

You got to pick your battles, I I guess is what I would say.

27:52

And focus hand wedding on that perennial weed itself.

27:57

Yeah.

27:58

So we know it’s slow, but what what are they running at now?

28:01

So the question is pace.

28:03

And I, I didn’t give you a definitive number because it depends on the crop, it depends on the weed species and it depends on how many weeds you have out there.

28:12

And that’s the goal with combining with these folks like at Eco Robotics is to try to clear as much out as easily as we can, focus on the hard to get pieces with the laser weeder, minimize that population.

28:25

But even, you know, when we’re going like a million weeds per acre and a specialty crop like onions, it can go about four acres an hour or so at this pace.

28:36

On a 20 foot wide 1, you double and then and that’s where the carbon dioxide version, which is less efficient.

28:43

So the 40 foot wide one they advertised as having triple the speed of the generation one tool.

28:48

That was in one year it changed like that.

28:50

I don’t know what they’ll have next year.

28:52

I don’t know.

28:53

We’ll see.

28:55

So any other questions, Greg?

29:00

Sorry.

29:00

There you go.

29:02

So this is this is wonderful and exciting.

29:06

I hear the but coming.

29:07

Yeah.

29:09

What has surprised you the most of your research?

29:14

Oh, Greg.

29:14

Yeah.

29:15

Great question by Greg.

29:16

And there’s a, my colleagues across the country including our collective colleagues family Culpepper in Georgia.

29:23

I can’t speak for him, but I’ve seen his research.

29:26

And I think collectively what we’re amazed by is how much injury we were causing with these sub lethal cumulative herbicide applications reducing yield and quality.

29:37

A lot of our herbicide evaluation work is done as individual pieces and we don’t leave untreated checks on a crop like that because I know what 0 looks like.

29:47

So no yield.

29:48

So what we were amazed by and the growers have been too is how much more yield we get out of this.

29:57

I’ll give you one other piece that I’m amazed by that needs more thought and progression.

30:02

But our onion growers in these specialty crops here and in New York, New Jersey have realized that when we caused that sub lethal herbicide injury, it makes those plants more attractive to insect pests and diseases like thrips and stem filium, leaf blight and insect factored viruses.

30:25

And the growers have noticed I don’t need to spray like I don’t know if they sprayed insecticide at all this year because their plants were darker green and less attractive to those that seek weak plants weakened by stressors, including herbicides.

30:40

So yield gain better quality and healthier plants.

30:45

And you see that in the picture.

30:46

Yeah.

30:46

Do you have any yield?

30:51

Do I have a yield comparison number?

30:54

Yeah, 31% yield increase this year over our herbicide standard.

30:58

Yeah, there’s a question.

31:00

Yeah, right.

31:14

So the question is, like many of these, is there a subscription fee for the services on a laser weeder?

31:20

And the answer is yes.

31:21

I can’t tell you all the details.

31:23

Part of it’s because it has many different options involved.

31:27

You know, the the high end being the remote operator, of course, that’s replacing humans on your farm.

31:33

but there are.

31:35

You could operate it with the existing system, but there’s a tech support piece.

31:39

There’s an extended warranty.

31:41

It’s very complicated, but there is a cost.

31:44

Yes.

31:44

Yeah.

31:46

What’s the outside of the cost of the machine, which will be coming down, what’s the operational cost, average per acre, you know, say fuel, What’s the cost to operate the laser?

31:58

Yeah, so what’s the cost to operate the laser?

32:00

I’ll just tell you the inputs, roughly.

32:01

You still need diesel on the tractor.

32:03

It’s not running on air.

32:05

So you need to run the tractor, which you would normally do anyways, but you’re covering a lot more ground because it’s only 20 or 40 feet wide.

32:14

So you have that piece and then unless you have a remote service agreement, you still have an operator in the tractor.

32:21

So those are the two primary costs related to it.

32:25

And obviously you’re depreciating a pretty expensive piece of equipment across there.

32:28

But the laser itself is cheap to operate.

32:33

So.

32:34

So your cost is tied up in the diesel, It’s PTO generated.

32:38

Yeah.

32:39

Did that answer?

32:40

Yeah.

32:40

On CO2, there’s CO2 lasers on generation 1, diode lasers on generation 2, which are much more efficient.

32:49

Yeah.

32:50

So one more quest, what’s the laser longevity?

32:54

What’s the laser longevity?

32:56

I’ll be back in 10 years and let you know they anticipate about 10 years.

33:01

Yeah, at this point, yeah, Yep.

33:03

Good questions though.

33:04

And with that, I know you all want to get outside.

33:06

Certainly appreciate your attention.

33:08

Appreciate letting a specialty crop sci-fi guy talk to you today.

▶ Spraying Is Easy, Doing It Right Isn't: Tips for Better Herbicide Applications

▶ Spraying Is Easy, Doing It Right Isn't: Tips for Better Herbicide Applications Adding Wheat to a Corn-Soybean Rotation to Enhance Pest Management

Adding Wheat to a Corn-Soybean Rotation to Enhance Pest Management ▶ Introduction to Common Crop Diseases

▶ Introduction to Common Crop Diseases