Much expense and time go into harvesting and storing good quality forage. You wouldn’t think of throwing away one third of this forage. However, this is what can happen without proper storage and feedout management. This fact sheet discusses storage feedout management strategies to help save valuable forage.

What losses occur when feeding dry hay?

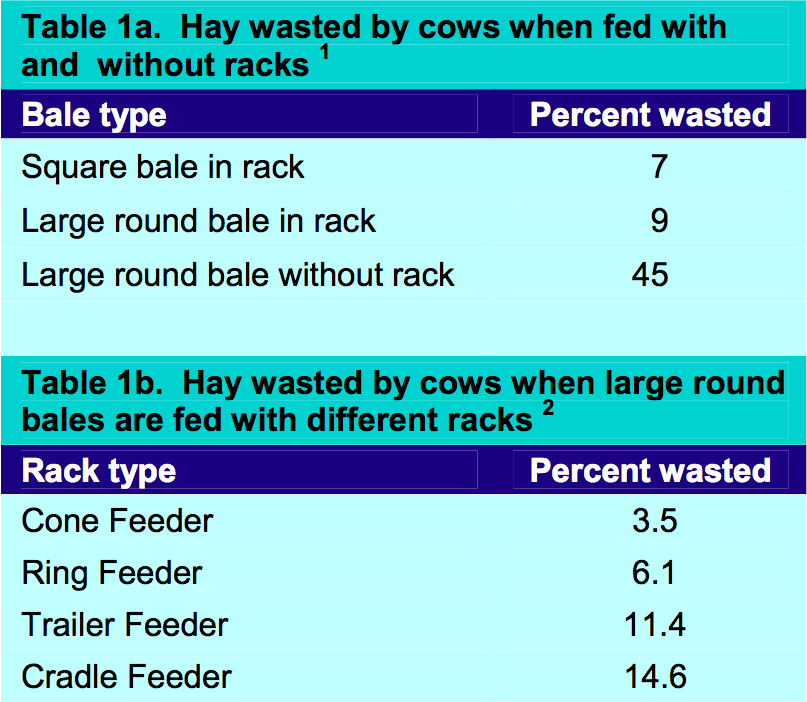

Limiting cattle access to dry hay bales is the single greatest way to reduce forage feedout losses. Livestock trample, over-consume, foul, and use for bedding 25 to 45% of hay when it is fed without restrictions (Table 1a).

Cattle waste less hay when they are limit fed. 25 to 45 percent more hay is needed when hay is fed with unlimited supply than when only a one-day supply is fed. A dry, pregnant cow will consume 20-30% more hay than her needs when allowed free access to hay. Daily feeding will force livestock to eat what they might otherwise refuse, over-consume, trample, and waste.

No matter how hay is fed, efforts to limit access to hay and offering a single day supply per feeding reduce hay losses.

What dry matter losses occur in silage storage systems?

Dry matter losses occur when aerobic organisms decompose the readily available carbohydrates in silage while in the presence of oxygen. These losses can occur in the silo mass when oxygen is entrapped due to inadequate packing, on the top surface due to oxygen penetration through the cover, or along the walls when runoff water percolates through the silage at the wall, when oxygen penetrates the walls, or when oxygen penetrates the feedout face during the feeding process.5

Dry matter losses during feedout occur with any silage storage system. Losses occur during the actual feedout and from refusal and wastage by animals. Maintaining anaerobic conditions within the storage structure are critical for long-term silage storage. Once the structure is open and silage is exposed to oxygen, dry matter loss begins to occur more rapidly as aerobic microorganisms consume the readily available carbohydrates. Maintaining a smooth, firm silage face while feeding out at an appropriate rate is key to reducing silage feedout losses. Packing the silo to a bulk density (as fed density) of more than 45 lbs AF/cu ft limits the porosity of silage which helps to limit the penetration of oxygen at the feed out face. Silage accumulated on the floor of the silo is exposed to oxygen for an extended period of time between feedings. The quantity of silage removed from the feedout face should be limited to that which will be fed during a given feeding.

What is the magnitude of the feedlot losses at the silo face?

Figure 1. Dry Matter Loss at the Feedout Face of a Silo as Influenced by Bulk Density and Feedout Rate

These losses are highly variable. The two primary factors affecting them are the porosity of the silage and the feedout rate. Porosity is a measure of the gas space surrounding the silage particles, and porosity decreases as bulk or as fed density increases. Feedout rate affects the amount of time silage is exposed to oxygen in the silo before being fed. As feedout rate increases, losses decrease. Figure 1 shows feedout losses as a function of bulk density and feedout rate. A goal of less than 3% dry matter loss during feedout should be established. From Graph 1, you can see bulk density of 40-50 lbs AF/cu ft and a feedout rate of greater than 6 inches per day are needed to achieve this goal.

How many inches of silage should be removed from the bunker face?

The removal from the face critically affects feedout loss and animal performance. Recommended removal rates are greater than 6 inches/day. Removal rates from a bunker/pile silo should never be lower than 4 inches/day in the summer and 3 inches/day in the winter. When designing bunker/pile silos, use a face removal rate of 12 inches per day. At no time should more than 3 days of silage be unprotected by plastic cover.

What bunker removal techniques are recommended?

Many methods of silage removal are used on farms. Perhaps the most common is the bucket loader. It is preferred that the face of the silage be scraped from the top and allowed to fall to the floor. Creating a small cavity at the base of the face and scraping into the cavity is another option as is scraping from one side of the storage to the other with the side of the bucket. Any method that results in dislodging the face silage, creating gouges, cracks and potholes exposes a larger surface area and allows air to penetrate deep into the stack leading to increased deterioration. A face cutter can reduce feed losses compared to a bucket loader.4 No matter what method is used to remove silage from a bunker it is important to closely estimate the amount of forage needed to ensure that all loosened forage is fed. Graph 1 presumes a smooth undisturbed feedout face. You can expect 1- 3% additional loss to the values of Graph 1 if the face is not smooth and/or is disturbed. The amount of additional loss with a rough surface is affected primarily by feedout rate, approximately 1% at 6 in./day removal rate and 3% at 2 in. /day8 removal rate.

How can dry matter losses be reduced in bags?

Remove at least 12 inches/day. Uncover only what will be used for that feeding. With bags, it is always important to close the bag off after each feeding to reduce losses. Some producers drape a chain or weighted rope over the top of the bag near the cut edge to help seal the plastic to the silage to reduce oxygen penetration between the plastic and the silage. The storage site of the bag is important to reduce feedout losses. If placed near a wet area or on a soft surface, removal will be difficult and additional forage could be lost. Wet soil can contaminate the feed as well. Hard packed gravel, asphalt and concrete surfaces have been used to avoid the problems of wet soils bases.

Is there dry matter loss with tower silos?

Feedout losses with tower silos can occur a few different ways. Make sure the silage is adequately fermented (fermenting for 30 days) before opening the silo. This will help the silage to have a low pH before feeding. Remove at least 4 inches/day from the surface. Dry matter losses occur as soon as oxygen is reintroduced to the silage. Bulk density in tower silos will be low in the top 20 feet so high feedout rates are needed in this zone to minimize exposure to aerobic organisms. Bulk density in the bottom 40 feet will be quite high (50-60 lbs. AF/cu. ft.) so the 4 inches per day will be adequate in this zone of the silo (Graph 1).

Dry matter losses due to wind can be high if the silage is directed into a conveyor with no protective shelter or cover. Properly stored silage in tower silos, which feed into a feeding station or feed room where wind will have little effect, can have the lowest feedout losses of any structure. Making sure all conveyors have covers, drop pans and liners will reduce losses. Holes in conveyor liners allow forage to fall through, subjecting it to wind loss or being unavailable to the animal.

How is feed loss limited during feedlot?

Since feedout losses begin when silage is exposed to oxygen, it is important to remove no more feed than will be fed in a given feeding. Not only is dry matter lost in the unfed silage, animal performance is also lost. For example, when dairy cows were fed corn silage that had been exposed for four days, dry matter intake dropped 38%.4

The ambient temperature has a major influence on the aerobic stability of silage. Dry matter robbing microbes increase exponentially with temperature up to 130°F. This means silage fed-out during warm weather deteriorates faster than silage fed in colder weather. If possible, attempt to feed several times per day on hot days.

Pushing up feed regularly to encourage animals to consume silage and reduce exposure to oxygen will reduce dry matter loss and refusal. If forages are left in mangers or bunks by milk cows, these forages can be fed to heifers or dry cows. Another way to reduce dry matter loss is to not overfill the feed wagon or TMR mixer. Forage spilled during mixing and in transport from the storage area to the animal can’t be recovered..

Resources

1. Anderson, B., and Mader, T., 1996, University of Nebraska, “Management to Minimize Hay Waste”, Publication G84-738-A.

2. Buskirk, D. D., A. J. Zanella, T. M. Harrigan, J. L. Van Lente, L. M. Gnagey and M. J. Kaercher.2003. Large round bale feeder design affects hay utilization and beef cow behavior . J. Anim. Sci. 2003. 81:109- 115.

3. Ishler, V.A., A.J. Heinrichs, D.R. Buckmaster, R.S. Adams and R.E. Graves. 1993., Harvesting and Utilizing Forage. Penn State University Circular 396. Pennsylvania State University. Cooperative Extension Service.

4. Management of Bunker Silos and Silage Piles, by Ken Bolton, Jefferson County Dairy and Livestock Agent, and Dr. Brian Holmes, UW Biological Systems Engineering Dept. https://fyi.extension.wisc.edu/forage/files/2014/01/mgmt-bunkers-piles-bjh2.pdf

5. Roth, G. and D. Undersander, editors.1995. Corn silage production, management, and feeding. NCR publication NCR574. American Society of Agronomy, Crop Science Society of America and Soil Science Society of America.

6. Pitt, R. E. and R. E. Muck. 1993. A diffusion model of aerobic deterioration at the exposed face of bunker silos. J. Agricultural Engineering Research. 55:11-26.

7. Holmes, B. J. and R. E. Muck. 2007. Packing Bunkers and Piles to Maximize Forage Preservation. Proceedings of the Sixth International Dairy Housing Conference. ASABE and Harvest and Storage page of Team Forage web site. URL: https://fyi.extension.wisc.edu/forage/files/2014/01/PackingBunkersPiles.pdf

8. Muck, R. E. and C. A. Rotz. 1996. Bunker silo unloaders: an economic comparison. Applied Engineering in Agriculture 12:273-280.